The permanent magnet synchronous servo motor is developed from the wound synchronous motor. It uses permanent magnets instead of electric excitation, thus eliminating the need for excitation coils, slip rings and brushes. Its stator current is basically the same as that of the wound synchronous motor. , the input is symmetrical sinusoidal alternating current, so it is called AC permanent magnet synchronous servo motor. What the editor is going to introduce below is the advantages and structure of the embedded permanent magnet synchronous servo motor. I hope everyone can understand it after reading it!

The rotor with surface permanent magnet structure embedded in the permanent magnet synchronous servo motor has a smaller diameter, low moment of inertia, large equivalent air gap, small positioning torque, and low winding inductance, which is beneficial to improving the dynamic performance of the servo motor; at the same time, this rotor The structural motor has small armature reaction, high linearity of torque-current characteristics, simple control and high precision. Therefore, this rotor structure is generally used in permanent magnet AC servo motors.

According to the above analysis, it can be seen that the permanent magnet synchronous servo motor with embedded permanent magnet rotor has the following advantages:

1. The permanent magnet is located inside the rotor. The rotor has a simple structure, high mechanical strength, and low manufacturing cost.

2. The outer surface of the rotor is made of silicon steel sheet, so the surface loss is small.

3. The equivalent air gap is small, but the air gap magnetic density is high, which is suitable for the control of weak magnetism.

4. The permanent magnet has a high degree of freedom in shape and configuration, and the rotor has a small moment of inertia.

5. This motor can effectively utilize reluctance torque to improve the torque density and efficiency of the servo motor.

6. It can also use the salient pole effect of the rotor to realize starting and operation without position sensors.

Therefore, permanent magnet synchronous servo motors with embedded permanent magnet rotors are suitable for fields requiring high speed, large torque, high power, high efficiency, field weakening control and a wide range of constant power speed regulation.

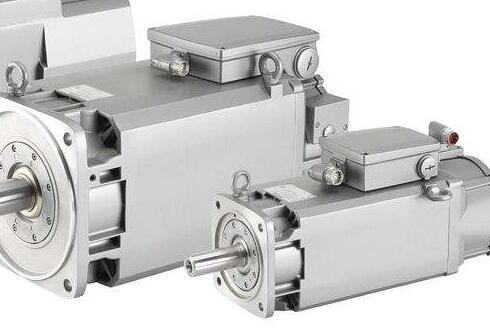

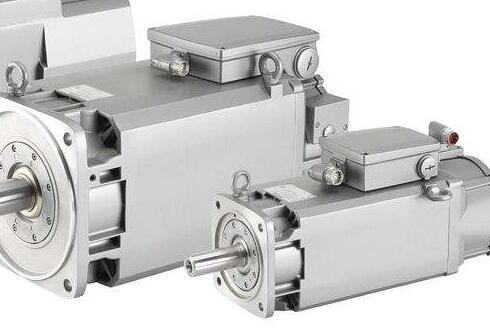

The permanent magnet synchronous servo motor consists of two parts: the stator and the rotor. The stator mainly includes an armature core and three-phase (or multi-phase) symmetrical armature windings, whose windings are embedded in the slots of the iron core; the rotor mainly consists of permanent magnets, magnetic yoke and rotating shaft.

The permanent magnet is attached to the magnetic yoke, which is cylindrical and is placed on the rotating shaft. When the diameter of the rotor is small, the permanent magnet can be directly attached to the magnetic shaft. The rotor is coaxially connected with position and speed sensors, which can be used to detect the relative position of the rotor magnetic poles relative to the stator winding and the rotor speed. When a symmetrical three-phase current passes through the armature winding of a permanent magnet synchronous servo motor, the stator will generate a rotating magnetic field that moves at a synchronous speed. In a steady state, the rotor's rotational speed is always the synchronous rotational speed of the magnetic field.