Features

1. To address the high starting torque requirements of water jet looms, our engineers have conducted an in-depth optimization of the structural electromagnetic design.

2. We have selected premium permanent magnets with advanced ultra-high intrinsic coercivity. These magnets possess a significantly higher intrinsic and magnetic coercivity, allowing them to maintain their performance even at elevated temperatures, up to 180 degrees Celsius.

3. High mechanical efficiency, low loss, large starting torque, low-temperature rise, reliable operation.

4. The high power factor of our water jet loom is a notable advantage, as it reduces line losses and voltage drops, and improves the overall power supply quality.

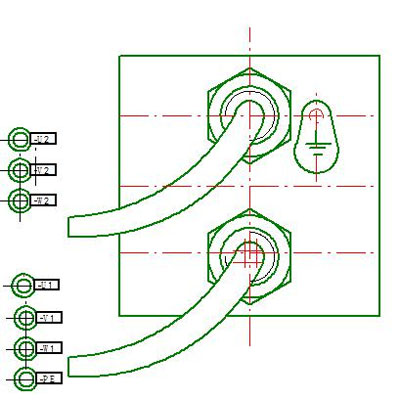

Wiring method

Specification

| Model | Rated Power | Rated Current | Rated Speed | Rated Frequency | Rated Torque | Efficiency | Power Factor |

| (kW) | (A) | (r/min) | (Hz) | (N.m) | (%) | (cosφ) | |

| TJY-112M-4 | 2.2 | 3.6 | 1500 | 50 | 14 | 89.7 | 0.99 |

| TJY-112M-4 | 2.8 | 5.3 | 1500 | 50 | 17.8 | 90.3 | 0.99 |

| TJY-112M-4 | 3 | 5.3 | 1500 | 50 | 19.1 | 90.3 | 0.99 |

| TJY-132M-4 | 3.7 | 6.6 | 1500 | 50 | 23.5 | 90.9 | 0.99 |

| TJY-132M-4 | 4 | 6.6 | 1500 | 50 | 25.5 | 90.9 | 0.99 |