I have introduced the selection comparison of servo motors before. It can be seen that each selection of this motor has different application fields and related advantages. We can choose servo motors according to our own needs. So what is the principle of servo motor encoder? And what kind of device is a servo encoder? Please read the detailed introduction below!

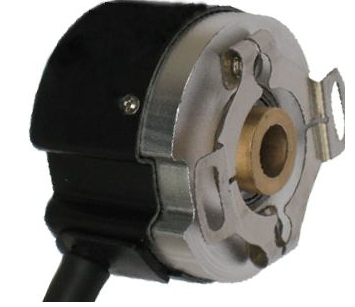

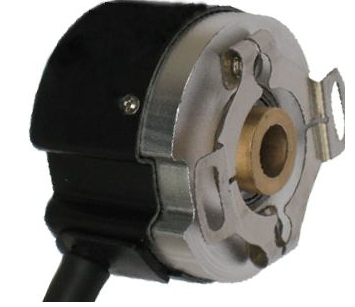

The servo motor encoder is a sensor installed on the servo motor to measure the magnetic pole position, servo angle and speed. From the different physical media, the servo motor encoder can be divided into photoelectric encoder and magnetoelectric encoder. In addition, the rotary transformer It is also considered a special type of servo encoder. Photoelectric encoders are basically used on the market. However, as a rising star, magnetoelectric encoders have the characteristics of reliability, low price, and anti-pollution, and have a tendency to catch up with photoelectric encoders.

The principle is as follows:

The basic functions of the servo encoder are the same as those of ordinary encoders. For example, the types include A, A inverse; B, B inverse; Z, Z inverse and other signals. In addition, servo encoders are different from ordinary encoders. That is, servo motors are synchronous motors. When starting a synchronous motor, you need to know the magnetic pole position of the rotor, so that you can start the servo motor with high torque. In this case, you need to equip several additional signals to detect the current position of the rotor, such as increment The servo encoder has UVW and other signals. Because of these signals for detecting the rotor position, the servo encoder seems a bit complicated, which makes ordinary people unable to understand its meaning. In addition, some manufacturers deliberately conceal some The signals and related materials are not complete, which adds to the mystery of the servo encoder.

Since the A and B phases are 90 degrees apart, the forward and reverse rotation of the encoder can be determined by comparing whether phase A or phase B is in front. After the zero pulse, the zero reference position of the encoder can be obtained.

The materials of the encoder code disc include glass, metal, and plastic. The glass code disc is deposited with very thin engraved lines on the glass. It has good thermal stability and high precision. The metal code disc is directly engraved with pass and non-pass lines and is not easy to break. However, since metal has a certain thickness, the accuracy is limited, and its thermal stability is an order of magnitude worse than that of glass. Plastic code discs are economical and have low cost, but their accuracy, thermal stability, and service life are poor. Some.

Resolution - The number of clear or dark lines that the encoder provides per 360 degrees of rotation is called resolution, also known as analytical graduation, or directly called how many lines, generally between 5 and 10,000 lines per revolution.

output signal:

1. OC output: It is the transistor output that was often mentioned before. When connecting, you need to consider the input impedance and circuit loop issues.

2. Voltage output: In fact, it is also a format of OC output, but it has a built-in active circuit.

3. Push-pull output: The interface is convenient to connect, and there is no need to consider NPN and PNP issues.

4. Differential output: good anti-interference, long transmission interval, servo encoders use this output method.