Zhejiang Jinyi Special Motor Co., Ltd. produces high-quality permanent magnet motors, and everyone is welcome to inquire. So what are the characteristics of permanent magnet motors? And what are its energy-saving principles? Let’s find out together next!

Features of permanent magnet motors:

Permanent magnet speed-regulated intelligent industrial motors can easily and effectively transform existing equipment without requiring modifications to existing reduction equipment and power supplies. Permanent magnet speed-regulated intelligent industrial motors require little protection work, are al protection-free products, and have ly low maintenance costs. It tolerates large installation alignment errors, greatly simplifying the installation and debugging process, thereby reducing operating and maintenance costs and reducing the owner's total cost of ownership.

Permanent magnet speed-regulated intelligent industrial motors have high reliability and low equipment failure rate. It can withstand various harsh environments, such as places with large voltage fluctuations in the power grid, high harmonic content, flammable, explosive, humid, high dust content, high and low temperatures, etc. It has a long service life and a design life of 20 years. The selection of permanent magnet speed-regulated intelligent industrial motors will neither cause damage nor shutdown due to power quality. Permanent magnet speed-regulated intelligent industrial motors do not produce pollutants or harmonics.

The energy-saving principle of permanent magnet motor is as follows:

1. The working principle of an asynchronous motor (induction motor) is that the rotating magnetic field of the stator generates an induced current in the rotor and generates electromagnetic torque. The magnetic field is not directly generated in the rotor. Therefore, the rotation speed of the rotor must be less than the synchronous speed (without this difference, that is, slip, there would be no rotor induced current), so it is called an asynchronous motor. The smart industrial motor rotor itself generates a magnetic field in a fixed direction (generated by permanent magnets or DC current), and the stator rotating magnetic field "drags" the rotor magnetic field (rotor) to rotate, so the rotor's rotational speed must be equal to the synchronous speed, so it is called a synchronous motor. The speed n of the intelligent industrial motor has always been n=60f/p, where f is the set frequency and p is the number of pole pairs of the motor.

Since there is no need to absorb reactive current from the power grid and there is neither copper loss nor iron loss on the rotor, the synchronous motor can maintain a power factor close to 1 within a wide load range, and the machine power is 8 times higher than that of an asynchronous motor of the same capacity. About %, the energy target (ηXcosΦ) improves by about 18%.

2. The power density of smart industrial motors is about 25% higher than that of asynchronous motors of the same capacity. For motors with the same power, smart industrial motors are two frame sizes smaller than asynchronous motors and are smaller in size, which means smaller iron losses and smaller mechanical losses.

3. Intelligent industrial motors have higher power than asynchronous motors of the same power, and at the same time have a wider high-efficiency area. When the speed range of intelligent industrial motors is 25%-99% of the rated speed, the power reaches 95%-97%, while the speed range of asynchronous motors is At 70%-99% additional speed, the power is only 88%. When the speed is lower than 70% additional speed, the power will drop sharply.

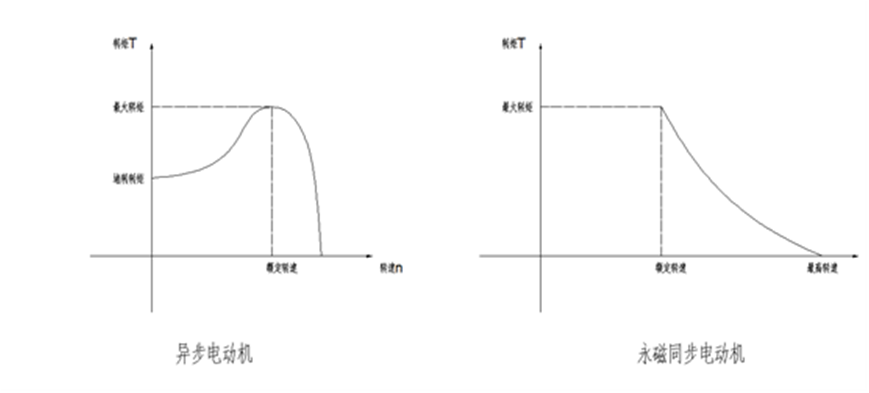

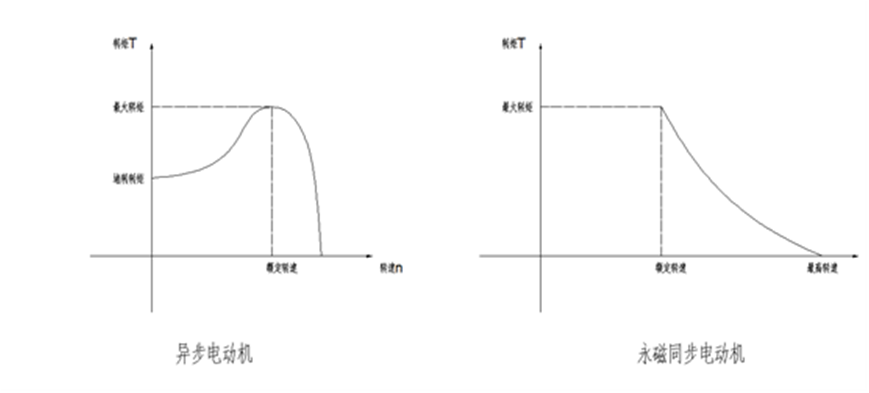

4. The torque comparison between intelligent industrial motors and asynchronous motors at different speeds is as follows:

5. When the asynchronous motor starts, the current is 6-7 times the rated current, which is detrimental to the life of the motor. In order to achieve the required torque, the motor type is even increased, and the motor is running at low load and the power is reduced. When a smart industrial motor starts, the current gradually increases and will not exceed the rated current, and the torque can also reach the rated torque. There is no current impact, which prolongs its service life and the motor is under reasonable load operation.

6. The speed control of permanent magnet motor is relatively precise; it has greater advantages in situations with high speed requirements.