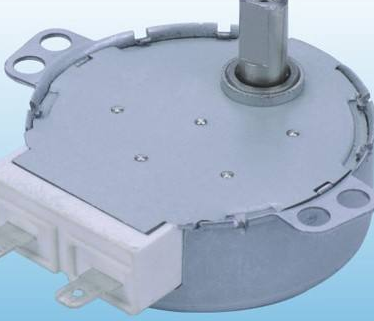

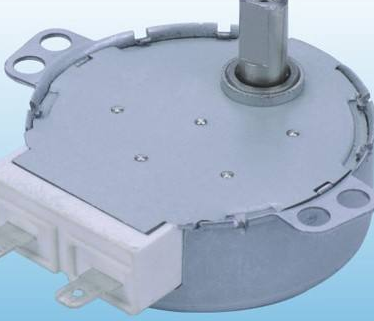

We learned about the structure of the permanent magnet synchronous motor last time. This motor is mainly composed of rotor, end cover, stator and other components. So what are the classifications of permanent magnet synchronous motor materials? Let’s take a look below!

The ferromagnetic material of the permanent magnet synchronous motor, the residual magnetism Br and the coercive force Hc are important parameters of the magnetic material. Generally, ferromagnetic materials are divided into soft magnetic and hard magnetic materials based on the size of Hc and the shape of the hysteresis loop.

The soft magnetic materials used in permanent magnet synchronous motors have narrow hysteresis loops, small remanence Br and small coercive force Hc. Common soft magnetic materials include cast iron, cast steel and silicon steel sheets. Because of their high magnetic permeability, they are used as cores in the manufacture of motors and transformers.

The hard magnetic materials used in permanent magnet synchronous motors have wide hysteresis loops, large remanence Br and coercive force Hc. Because of the large remanence, they can be made into magnets. Because they are not easy to demagnetize, hard magnetic materials are also called Permanent magnetic material. The performance of permanent magnet materials is generally demonstrated by three-phase indicators of remanence Br coercivity Hc and magnetic energy product (BH) mex. Generally speaking, the larger the three-phase target is, the better the magnetic function of the material is. In addition, factors such as the operating temperature, stability and corresponding price of the material must also be considered.

The commonly used permanent magnet materials for permanent magnet synchronous motors include the following:

: Alnico. It is an alloy of iron and nickel, aluminum and cobalt. Its advantages are larger Br, higher magnetic function, better stability, and cheaper price. Its disadvantages are small Hc, weak resistance to demagnetization, and the material is hard and brittle.

Second: ferrite. It is a composite compound of iron and one or more metal elements such as strontium and barium. Its advantages are large Hc, strong resistance to demagnetization, low price, small specific gravity, and no need for work stability treatment. Its disadvantage is that Br is not large, and temperature has a greater impact on the magnetic function, so it is not suitable for temperature changes. big occasion.

Third: Rare earth cobalt. Its advantages are better induction performance, strong resistance to demagnetization, good magnetic temperature stability, and high allowable operating temperature (200~250°C); its disadvantage is that it is more expensive. At present, the rotor of permanent magnet synchronous motor mainly uses earth cobalt material.

Fourth: NdFeB. Its characteristics are better induction function and low price; its disadvantage is that the allowed working temperature is lower (about 120°C), because it contains more iron and neodymium, so it is easier to be corroded.