There are three excitation methods for permanent magnet synchronous motors, which I have introduced in detail before. What types of driving methods can be divided into permanent magnet synchronous motors? And what are the characteristics of each driving method? Next, we will discuss this issue as follows!

According to the requirements of different industrial and agricultural production machinery, permanent magnet synchronous motor drives are divided into three categories: fixed speed drive, speed regulating drive and precision control drive. The details are as follows:

1. Fixed speed drive

There are many production machines in industrial and agricultural production that require continuous operation in one direction at a roughly constant speed, such as fans, pumps, compressors, general machine tools, etc. In the past, of these machines were driven by three-phase or single-phase asynchronous motors. Asynchronous motors have low cost, simple and reliable structure, and easy maintenance, so they are very suitable for driving this type of machinery. However, asynchronous motors have low power, power factor, and large losses, and this type of motor is widely used in large quantities, so a lot of electric energy is wasted in use. Secondly, fans and water pumps used in many industries and agriculture often need to adjust their flow, which is usually accomplished by adjusting dampers and valves, which wastes a lot of electrical energy. Since the 1970s, people have used frequency converters to adjust the speed of asynchronous motors in fans and water pumps to adjust their flows, achieving considerable energy-saving effects. However, the cost of the frequency converter limits its use, and the low power of the asynchronous motor itself still exists.

2. Speed regulating drive

There are quite a few working machines whose operating speed needs to be set and adjusted arbitrarily, but the speed control accuracy requirements are not very high. This type of drive system has many applications in packaging machinery, food machinery, printing machinery, material handling machinery, textile machinery and transportation vehicles. In this type of speed regulation applications, DC motor speed regulation systems were ly used at . With the development of power electronics and control technology after the 1970s, variable frequency speed regulation of asynchronous motors rapidly penetrated into the original application fields of DC speed regulation systems. . This is because on the one hand, the performance and price of the frequency conversion speed control system of asynchronous motors are completely comparable to those of DC speed control systems. On the other hand, asynchronous motors have simpler manufacturing processes, higher power, less copper consumption and less maintenance than DC motors with the same power. Advantages include easy maintenance. Therefore, asynchronous motor frequency conversion speed regulation has quickly replaced the DC speed regulation system in many occasions.

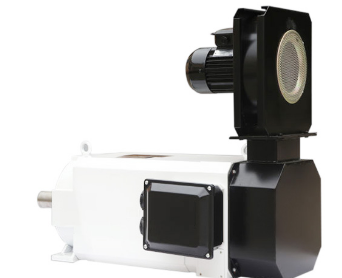

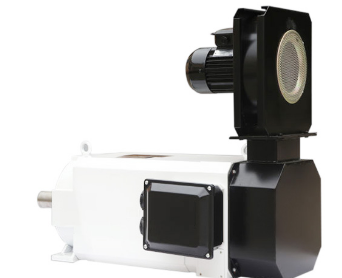

AC permanent magnet synchronous motor is a low-carbon motor in today's society because of its small size, light weight, high efficiency and energy saving. It has attracted more and more attention because the operating characteristics of permanent magnet synchronous motors and their control technology have become increasingly mature. Small and medium-power DC motors and asynchronous motors are gradually being replaced by permanent magnet synchronous motor speed regulation systems. Elevator drives are a typical example. The elevator drive system has certain requirements for the acceleration, steady speed, braking, and positioning of the motor. In the early days, people used DC motor speed control systems, but the disadvantages were low power and difficult maintenance and upkeep.

In the 1970s, frequency conversion technology matured, and the variable frequency speed regulation drive of asynchronous motors quickly replaced the DC speed regulation system in the elevator industry. In the past ten years, the elevator industry has gradually adopted the permanent magnet synchronous motor speed control system as the driving technology. It is small in size, energy-saving, has good control functions, and can be easily made into low-speed direct drive, eliminating gear reduction equipment; it has low noise, flat floor The accuracy and comfort are to previous drive systems, and it is also suitable for use in machine room-less elevators. The permanent magnet synchronous motor drive system has quickly become popular in various industries, and various inverter series products supporting it have been launched by many brands.

3. Precision control drive

① High-precision servo control system

Servo motors play a very important role in operation control in the field of industrial automation. Different application situations have different control function requirements for servo motors. In actual application, servo motors have various control methods, such as torque control/current control, speed control, position control, etc. The servo motor system has also experienced DC servo system, AC servo system, stepper motor drive system, and in recent years, it has become the permanent magnet motor AC servo system that is obvious to all. In recent years, of the imported automation equipment, automatic processing equipment and robots use AC servo systems of permanent magnet synchronous motors.

② Permanent magnet synchronous motor in information technology

Today's information technology is developing rapidly, and various computer peripherals and office automation equipment are also highly developed. Micromotors, the key components supporting them, are in great demand, and their accuracy and function requirements are getting higher and higher. The requirements for this type of micromotors are miniaturization, thinness, high speed, long life, high reliability, low noise and low vibration, and the accuracy requirements are particularly high.