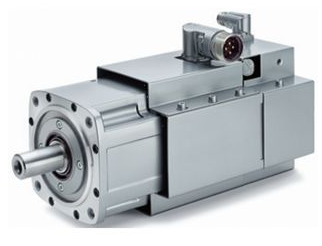

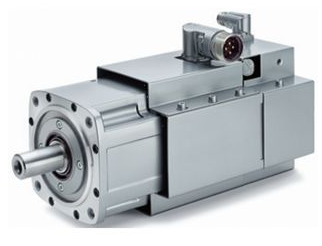

Before designing the permanent magnet synchronous motor, we must understand the structure of the permanent magnet synchronous motor. We introduced the structure of this motor in detail last time. So what are the design and optimization methods of permanent magnet synchronous motors? Next, please read the detailed introduction below!

Electromagnetic design is the key point and difficulty in motor design. However, the development of permanent magnet synchronous motors is later than that of asynchronous motors. It was only with the invention of permanent magnet materials in the 1980s that they were applied and promoted.

The design and optimization methods are as follows:

1. Analytical method. This method is ly used in the design of surface-mounted permanent magnet synchronous motors. Through Maxwell's electromagnetic field theory, the partial differential equation of the motor's vector magnetic potential or scalar magnetic potential is established, and the corresponding boundary constraints are substituted to analytically solve parameters such as magnetic induction intensity distribution, induced electromotive force, electromagnetic torque, and cogging torque. Permanent magnet synchronous rotors generally use finite blocks of permanent magnets with different magnetizing directions for excitation. The magnetic field distribution is not easy to analyze directly. Fourier expansion of the magnetic potential of the permanent magnets can be performed to calculate the general solution of the fundamental wave and various harmonics in the equation. Finally, the individual components are added up. Generally, two methods can be used to analyze the impact of stator slots on motor performance. One is the conformal transformation method, which converts the slotted stator model into a slotless stator model through certain mapping conditions; the other is the subdomain method. That is, the stator slot area is divided into finite sub-areas for solution, and the connections between each area are processed through boundary constraints. The analytical method has the characteristics of simple operation and convenient implementation. Through reasonable modeling, the expressions of motor functional parameters and structural parameters can be obtained. However, the analytical method generally approximates the core magnetic permeability to infinity during the design process. As the fullness of the motor's magnetic circuit and the complexity of the stator and rotor structures increase, the design accuracy will drop sharply.

2. Equivalent magnetic circuit method. This method is commonly used in various electromagnetic designs. It equates the magnetic circuit to a circuit, and uses Ohm's law of the magnetic circuit to establish equations for the magnetic circuit's reluctance, magnetomotive force and magnetic flux to solve. The design of the permanent magnet synchronous magnetic circuit is different from that of electric excitation motors. In addition to the air gap, the yoke and teeth of the stator and rotor, the magnetic flux track also contains permanent magnets. The magnetic circuit needs to be designed according to the material, structure, size and magnetization direction of the permanent magnets. Make reasonable equivalencies. The flux leakage magnetic circuit of permanent magnets in permanent magnet synchronization is relatively complex, and the flux leakage coefficient is large. In order to improve the accuracy of motor design, the influence of each flux leakage path should be fully considered, and if necessary, it should be modified appropriately based on engineering needs. The equivalent magnetic circuit method generally takes into account the saturation and nonlinear characteristics of the stator and rotor core materials as the magnetic permeability is infinite. It can also improve the design accuracy through nonlinear iterative solution. The equivalent magnetic circuit method has the characteristics of small calculation amount and clear physical meaning, and can conveniently calculate the operating point of the permanent magnet in permanent magnet synchronization. This method is often used in the preliminary design and design comparison of permanent magnet synchronization; however, this method The design method is less comprehensive and relies heavily on the experience of the designer. Various experience correction coefficients need to be introduced during the design process to meet the engineering design requirements.

3. Finite element method. The essence of this method is to divide each solution area of the motor into a limited number of connected units, establish a partial differential equation with boundary conditions for each unit based on the electromagnetic field theory, and convert the definite solution problem into a system of algebraic equations by using variation and discretization. Solve. With the rapid development of computer technology, computers are now generally used to perform nonlinear iterative operations on the finite element method, and finally a numerical solution that is very close to the analytical solution is obtained. In addition to effectively designing the motor magnetic circuit, the finite element method can also solve motor design problems that are difficult to handle with the analytical method and the equivalent magnetic circuit method by constructing a three-dimensional finite element model, such as permanent magnet end effects, stator skews, slopes, etc. The influence of motor magnetic circuit dispersion. The use of the finite element method to design permanent magnet synchronous motors has the characteristics of high calculation accuracy, and has been used by many experts and scholars as a primary or auxiliary method in motor design; however, the use of the finite element method for motor design and optimization often requires a large amount of amount of operations.

In the design process of permanent magnet synchronization, it is generally necessary to combine various optimization algorithms to optimize the parameters. That is, through the optimization algorithm, reasonable design parameters can be conveniently and quickly found to ensure the functional indicators of the designed motor. The problem of selecting an electromagnetic design model to design a permanent magnet synchronous motor can be attributed to a mathematical optimization problem with boundary constraints. Typical optimization goals mainly include motor power, permanent magnet structural dimensions, motor cogging torque, motor torque density, etc., as well as a combination of the above indicators. In order to improve the design power, the sensitivity of various parameters in motors around the world can often be analyzed to select design parameter variables that have a greater impact on motor performance as the design variables of the motor. Because the design problem of permanent magnet synchronous motor has the characteristics of multi-objective, multi-variable, non-linearity, etc., it is difficult for traditional optimization algorithms to complete the overall design. Therefore, many experts and scholars at home and abroad have focused on this problem and have solved a large number of problems with global search capabilities and easy convergence. Random optimization algorithms have been tried, such as surface response method, genetic algorithm, population algorithm, taboo algorithm, Tabu algorithm, etc., and have achieved certain results.